News and Events

Check out news and events happening with EVS retro Glazing and the team.

Check out news and events happening with EVS retro Glazing and the team.

ABOUT US

Welcome to EVS Window Technology and here is our story!

EVS is a relatively new company that was established by Michael and Catherine to develop new ways of glazing that are smarter and easier than existing industry processes. (Like many successful Kiwi business's we started off working from our garage) The simple idea started with the idea of attaching an extra glazing panel to an existing window. Yes, it has already been done and is commonly called ‘secondary glazing’ and there are already a range of secondary glazing products on the market. However, the big problem with secondary glazing is that it generally ends up trapping moisture between the old and new panels which results in permanent condensation that builds up and needs regular cleaning or replaced by regular double glazing. This was the first problem to solve.

Mike and Catherine had been learning about straw bale homes, as part of this process they attended a course to learn about natural earth plasters and how they work in home building. One interesting thing they discovered was how clay acted to absorb and release moisture and using it as a interior wall finish helped regulate humidity levels. We figured out we could harness this superpower of natural clay and apply it to our new glazing process as a way to capture and release trapped moisture. Normally double glazing units are sealed and have a synthetic desiccant (silica) that acts to absorb trapped moisture. But this artificial material is designed to hold onto the water, rather than release it again, which means once the seal breaks ( it inevitably always does) the silica fills with moisture then causes the panel to fail.

In our initial experiments we wanted to capture moisture using the clay and then show how it would vaporise and release as temperatures inside the glazing panel increased. Using a couple of plastic bottles we put a small hole and a small amount of water into the tops of each bottle, with one having Bentonite clay inside the cap (the same stuff as they use for kitty litter we discovered). The results, after a couple of weeks the bottle with clay had practically no condensation while the other bottle remained with a lot of condensation.

We then designed 3D printed vents that would allow a small amount of ventilation and hold the Bentonite clay. One of our first test projects was Catherine’s Mum, she allowed us to double glaze her home using our new idea. Needless to say her windows are still working well after 5 years. We have gone on to lodge global patents for this idea and continued our development process with major improvements to our venting and attachment processes. With the test of time and further refinement of a number of minor issues our EVS panels have continued to remain reliable.

Local Dunedin company, J-Tech Plastics helped start off our manufacturing by making our injection molded parts and we are still using them today. We are so grateful for their on-going help and support, every time we want to make a new complicated part, Jason cheerfully rolls his eyes but manages to achieve what we are looking for.

After finding New Zealand manufactures would not only take longer but cost considerably more we made the decision to investigate Chinese companies to manufacture our uPVC profiles. We are delighted with the quality and help that our Chinese colleagues have provided us . Dr. Argy Song, from Dunedin, also provided much needed

communication support in our dealings with the various Chinese companies, we are grateful to him for this.

In 2021 we undertook a BRANZ appraisal , BRANZ tests and measures the performance of building products for the building industry. Initially the BRANZ staff were skeptical of our new glazing product being able to withstand high wind loadings with our clip fixing system only capable of holding small loads.

However they had not factored in the combined strength of the sealant that resulted in them not being able to test our product to destruction. They simply couldn't break our test panels using their pressure test that mimicked the effects of extremely high wind loadings even after it was wound all the way up to its highest level. We were delighted to also get our insulation level rated at R0.59 which is one of the highest retro-glazing ratings in the industry as well as being well over the new glazing standards for new homes in the coldest zone (R0.50)

The effect of gaining the BRANZ appraisal has also led us to being able to offer a range of glazing IGU’s from New Zealand glass IGU manufacturers who had previously not wanted to be associated with our new system.

After installing 1000’s of panels, 5 years of successful installations and receiving our BRANZ appraisal, we are still facing industry skepticism after submitting our new inventive system for an industry award (WGANZ) for innovation!

We were surprised to find out that the judges had decided that there were to be no innovation awards this year! Wow, that is sad to think that an industry that needs innovation and development isn't doing anything to encourage and reward its members for thinking outside the square.

After being disappointed about the lack of industry support we are encouraged by our customers and their gratitude and belief in our products and their appreciation of being able to preserve their heritage windows after no other solutions had been provided previously.

We see the general lack of industry innovation as our opportunity to listen to what customers are wanting, and continue our program of innovation. The opportunities are global, to find more affordable ways to make existing homes warmer and dryer and help reduce our carbon footprint with less energy. We are continuing our product development with the development of a new build glazing system that will provide the highest performance ratings as well as novel features that combine fresh air ventilation with a heat exchange system, that is built into each panel. This will help address the need for warmer dryer windows combined and good ventilation that is lacking in most homes. Our first shipment has just arrived and we are getting underway with our first test project. We will also be looking to get this new product BRANZ appraised before we can offer this product to the market for new builds as it will need to have all its complaisance and performance measures meet New Zealand building code standards before it can be used in the building industry.

EVS have also developed a range of Draught stop products that seemed to be missing in the market place. When we were in China visiting our manufacturing factory for our EVS windows, we were shown some other materials that we hadn't seen before. We were introduced to aerated PVC which looked and felt like natural timber. After trying to make our own draught stops out of timber we suddenly thought that this new material would be an ideal material because it was prefinished, it was water proof, it was easy to cut, etc. etc. so we did a design and had it manufactured. This product has been so successful that we have been accepted as a the main supplier to Kianga Ora (the New Zealand government agency for social housing) as well as selling it around the country.

All these products are developed around understanding what the problems are and finding better ways of providing solutions. We see lots of opportunities for innovation in an industry that is stuck doing things the old ways so we are looking to continue growing our coverage and product development into the future. We are willing to venture into the unknown and try new things (yes that is a scorpion that Catherine is eating)

You may be wondering what ‘E’V’S’ means? when it stands for Externally Vented System based on our invention to externally vent glazing panels. Its probably not the best name for our business but most people just think of us as E-V-S and that keeps it simple.

Back ground in

Graphic design

Web development

Software Development

House design and building

Business Development

Background in

-Joinery and Building

-Marketing

-Hospitality

Background in

-Quantity surveying

-Building supply industry

The Otago pair found adding clay to window frames makes all the difference.

Source: 1 NEWS

A Kiwi couple's innovation could help improve living standards in thousands of homes around the country.

Their new technique for retro glazing windows slashes the cost of double glazing, a luxury which has previously been too expensive for some.

When Mike Hodges and Cathy Mann started building their dream home in Central Otago, they were inspired to experiment with a clay they were using in the build.

"Clay absorbs condensation, it's called a desiccate, that's what sort of got us thinking and playing around with clay and trying to use that as a material to see if we could create a new window that we could use to create a secondary glazing product," says Mike Hodges of company, RetroWood.

Adding another layer to existing windows was their simple ventilation technology to prevent condensation between the glass.

And homeowners are already seeing a big difference.

"The condensation, it's a non-event anymore we don't have any condensation on the glass," says homeowner, Brian Hyland.

Around ninety per cent of Kiwi homes could benefit from double glazing but it hasn’t been included in the new housing standards as it was deemed too expensive.

It’s hoped this technique could change that.

Otago Daily Times

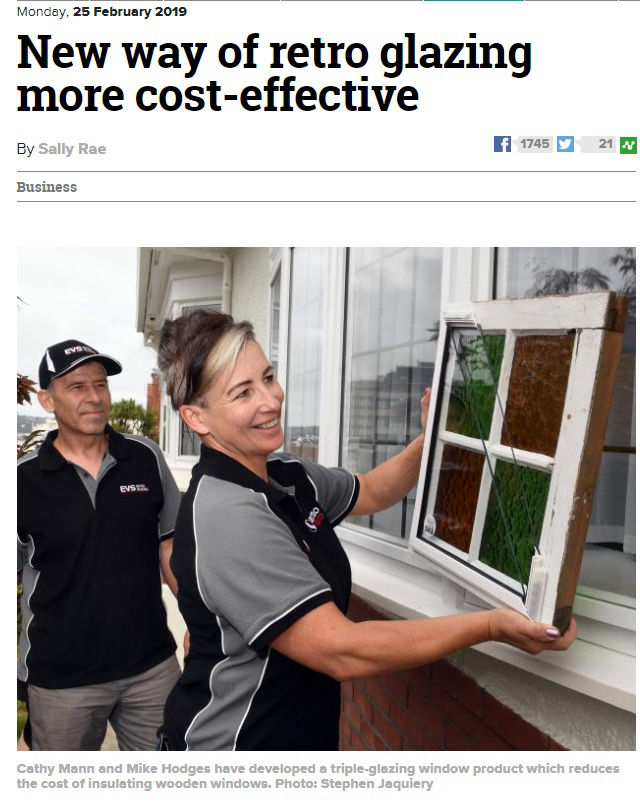

Monday, 25 February 2019

New way of retro glazing more cost-effective

By Sally Rae

...they developed a way of retro glazing character homes, using a new triple glazing system which they said was much more cost-effective than simply retro double-glazing.

The solution was an external secondary glazing panel fitted to the outside of a timber window; it was faster to install and could provide double or triple glazing results.

They started exploring ways to make the process easier and quicker. The biggest challenge had been to find a way to prevent condensation accumulating inside the window panels, a common problem shared by most secondary glazing systems.

Stuff.co.nz COLLEEN HAWKES

08:50, Nov 16 2015

There are many definitions of the word "grand". And with Grand Designs projects, sometimes it's the scope of the ambition that is grand, rather than the house itself.

For example, I'm not sure you would ever call a straw bale house grand, but when a couple sets out to handcraft such a home by themselves, then I guess that's a pretty grand ambition.

Phone: +64 (0) 274346912

Email: info@evsglazing.nz