Remove window panels

Panels are removed by first cutting through the paint around the edges between the panel and the frame then the panel can be taped out using a block and gentle tapping or using a multi-tool to cut the nails holding the panel.

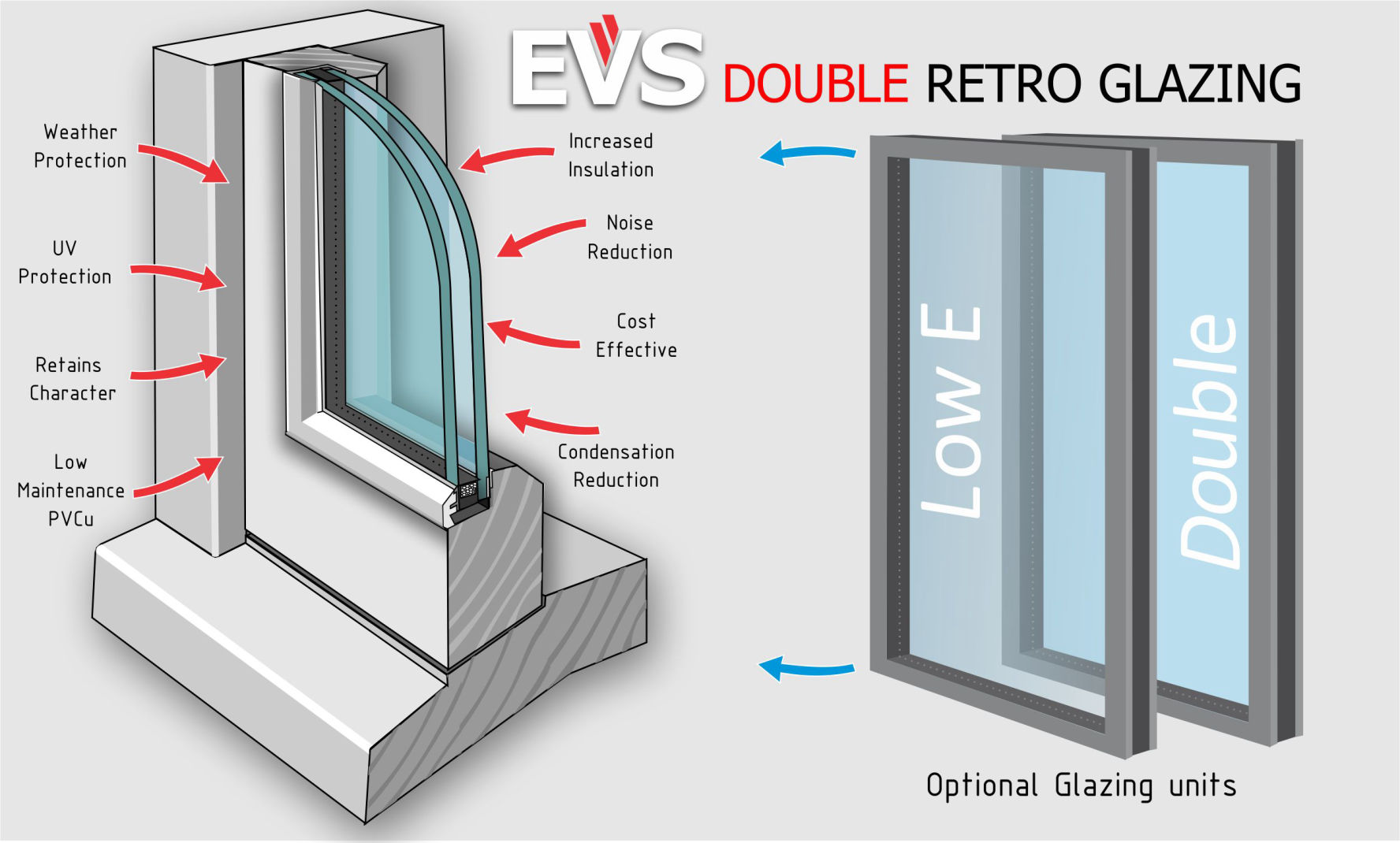

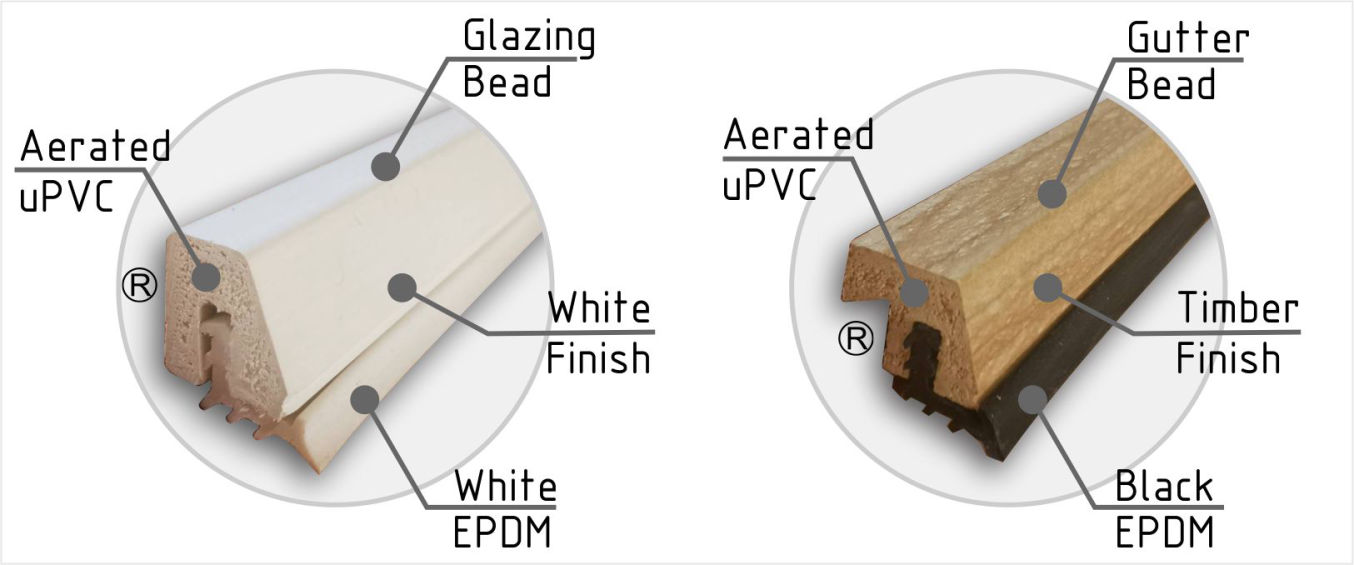

Retro fitting Double Glazed units to existing timber windows is a great way to upgrade your windows as well as maintain their character. The process does require a skilled joiner to remove the existing glass and install the new panel. EVS has now developed a new Glazing bead that integrates uPVC beading with a rubber (EPDM) seal for superior protection and finish.

The EVS Double Retro Glazing system follows industry standards when it comes to specifying glass and securing the glass with suitable glazing blocks and edge clearances. Where EVS stands out from the others is the design of the glazing beads follows the EVS method of using air vents to provide air movement around the installed glazing panel. Trapped moisture very rarely flows out from the drain holes unless there is an excessive amount of moisture getting into the cavity, so air vents work better to remove moisture that would otherwise cause rot or panel failure. The PVC and EPDM rubber seals also serve to provide a long lasting bead seal.

uPVC that looks and feels like timber, but doesn't absorb moisture nor does it warp or split. Ideal for cutting, sanding pinning and sealing, it makes for a longer lasting glazing bead with a low profile to minimize its visual impact. Its rolled corners and non shiny surface provide a solid base for a quality paint finish that wont split of flake off.

The wedge seals are made from rubber (EPDM Ethylene Propylene Diene Monomer) which don't shrink and have a high UV resistance. The special profile shape is designed to maximize the seal around the edge to prevent dust and moisture getting past.

EVS glazing beads are the most advanced, durable and arguably most attractive, all round solution for timber retro double glazing.

Panels are removed by first cutting through the paint around the edges between the panel and the frame then the panel can be taped out using a block and gentle tapping or using a multi-tool to cut the nails holding the panel.

The glass needs to be removed by using a biscuit cutter router blade from the inside and a skill-saw cut on the outside that neatly intersects to remove the putty edge as well as create a suitable rebate for the new glass unit.

There is sometimes rot and flaking paint that needs attention before the new glass is installed. Rot will need to be completely removed and either re-built with timber or epoxy fillers and timber treatments. Reinforcement screws should also be added to each corner. Finally all the exposed timber needs to be prepared and painted with a suitable primer.

A properly installed primary seal is important to prevent water pumping inside. Often there is a pressure difference between outside and inside and if there are gaps around the edge of the window then the pressure will suck moisture into the edge of the unit which can cause leaks, rot, and potential premature failure of the glazing panel.

It is important to allow room around the IGU to ensure any moisture that gets in, can either drain or vent out. Some installers will suggest that they use a sealant around the internal edges but this is a risky because water can suck into the gaps and cause premature failure of the glazing panel. It is important to also have suitable glazing blocks holding the panels in the correct position, particularly along the bottom to provide a suitable drainage gap

The Glazing Beads are the primary defense against moisture getting in, so they need to be attached firmly with no gaps around the edges or in the corners. Some installers just use timber glazing beads, Butyl tape and sealants which need high levels of paint maintenance due to the constant movement of timber, EVS uPVC beads provide a more stable long term solution

The Panel needs to be reinstalled back into its frame and if its an opening panel then its a good opportunity to replace the old hinges and if its a fixed panel then its best to pre-drill for a galvanized nail rather then a screw, so they can be removed easily in the future. Screwing and gluing the frame in make it very difficult for any future maintenance.

Painting is very important and often installers will require you to paint the panel within a few months in order for your warrantee to be valid. The most important thing is to ensure there is a good paint seal around the edges of the glass especially on timber bead systems, where any moisture that gets through will accelerate premature failure of your glazing system.

The low insulation value of (R0.19) on single glazed panels causes heat loss and condensation in poorly vented rooms. Upgrading with retro glazing will improve your single glazed window.

The EVS Double Retro Glazing fitted with standard glazing (R0.36) still has a high insulation value compared to Aluminum double glazing (R0.26). It is ideal for allowing the sun to warm your home.

EVS Double Retro glazing fitted with Low-E argon panels provides a top preforming (R0.53) for a retro fitted window solutions. The Low-E provides higher insulation against heat loss as well as heat gain.

Large drain holes provide a perfect home for insects and can clog up with spiderwebs and prevent the units from draining. EVS uses smaller drain hole/vent system at the top and bottom that are less affected by insects.

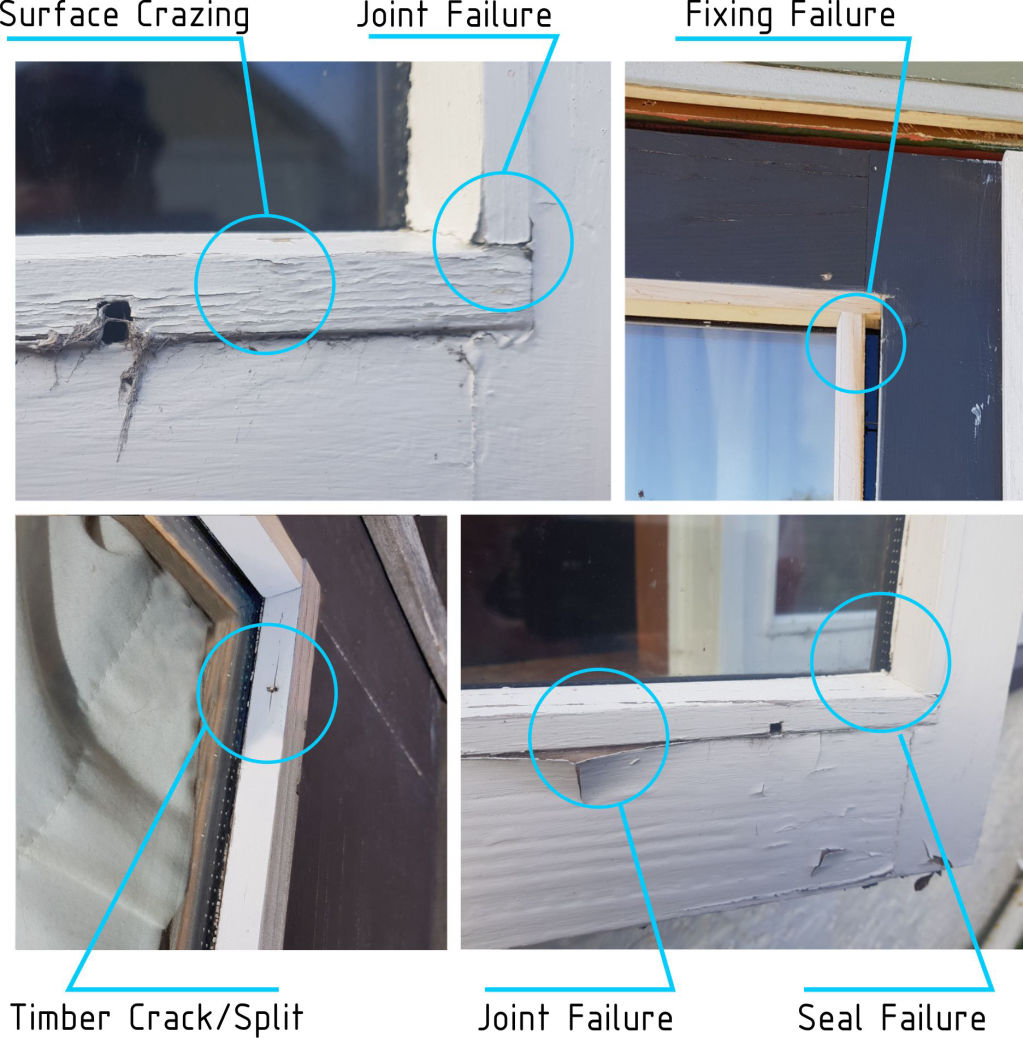

Timber that gets wet can swell and then dry out causing stress on the paint finish that eventually causes crazing, which intern lets more moisture in and accelerates the deterioration of the paint. EVS's uPVC glazing beads don't absorb moisture so wont cause surface flaking

Poorly sealed timber glazing beads will allow moisture to twist and bend the timber beads which can increase the chance of the panel coming loose from its fixings. EVS's uPVC glazing beads don't bend or twist and will remain in place.

Timber can split during the fixing process and overtime water can get into the crack and cause the pins to rust and the paint to split around the crack. EVS's uPVC glazing bead doesn't split because of its aerated structure

Poorly sealed timber glazing beads will move from increased moisture which will place strain along the painted joints and cause the paint to fracture and peel off. EVS's uPVC glazing beads have EPDM rubber seals that don't shrink or move and don't allow moisture to get past.

Seal failure around the edges of timber glazing beads is the main cause of failure, because most glazing beads are fixed with Butyl tape and sealant that relies on skilled installers and ongoing maintenance. EVS's uPVC glazing beads uses a multi finned rubber seal that provide more reliable and consistent seal over a longer time frame.

Download your Copy

You can download your copy of the EVS Double Retro Glazing PDF (A4 Format)

EVS_Double_Retro_Glazing.pdf

Download the Booklet format

EVS_Double_Retro_Glazing_Booklet.pdf

Phone: +64 (0) 274346912

Email: info@evsglazing.nz